INDUSTRIAL PROCESS/RAW MATERIAL

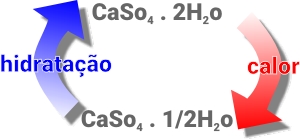

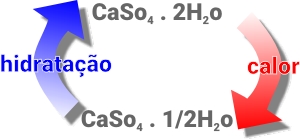

The laminated gypsum boards manufacturing is a phased process with several steps for each phase. After the first stage of crushing and grinding the raw material, calcium sulphate (CaSo4 • 2H2O), is heated and partially dehydrated (calcined) giving rise the gypsum commonly known as "plaster" (CaSo4 • 1/2H2O), and stored in powder form in vertical silos. Raw material stage and in the first phase completed.

The particular characteristic of the stucco is that mixed with the appropriate amount of water to produce a smooth plastic mass and molded in any desired shape. When the hardening of the mass occurs, the gypsum restores its chemical structure identical to the original mineral state.

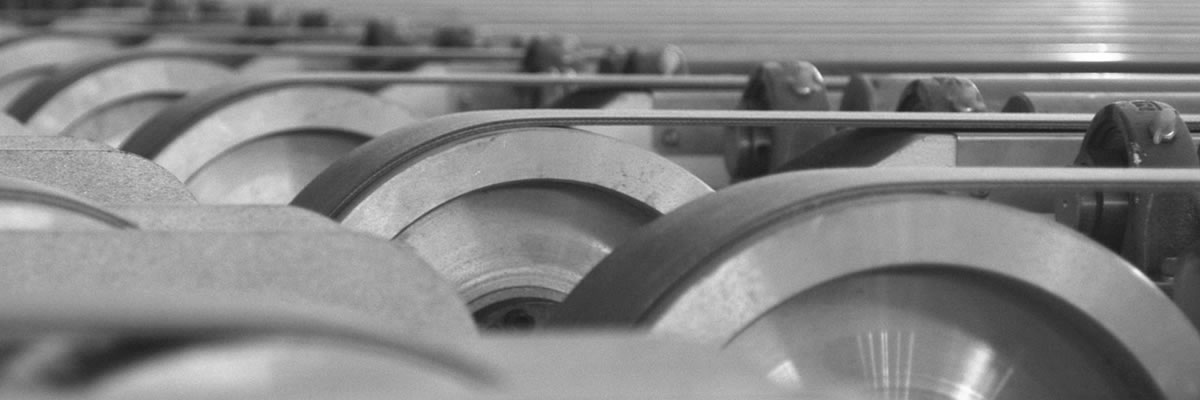

In the second stage of the gypsum laminate manufacturing process, the raw material is mixed with additives and water in the proper amount and exturdida on a continuous production line in quick motion between two layers of paper / special card.

The gypsum board is allowed to hydrate before being cut to the desired length. The process ends in "Gypsum oven" where high temperatures remove excess water plate, accelerating the gypsum mineralization process.